About Abyss

Abyss provides Asset Integrity Management software in the energy sector. I joined Abyss as their first product designer with the task of designing the second version of their program Fabric.

Project Overview

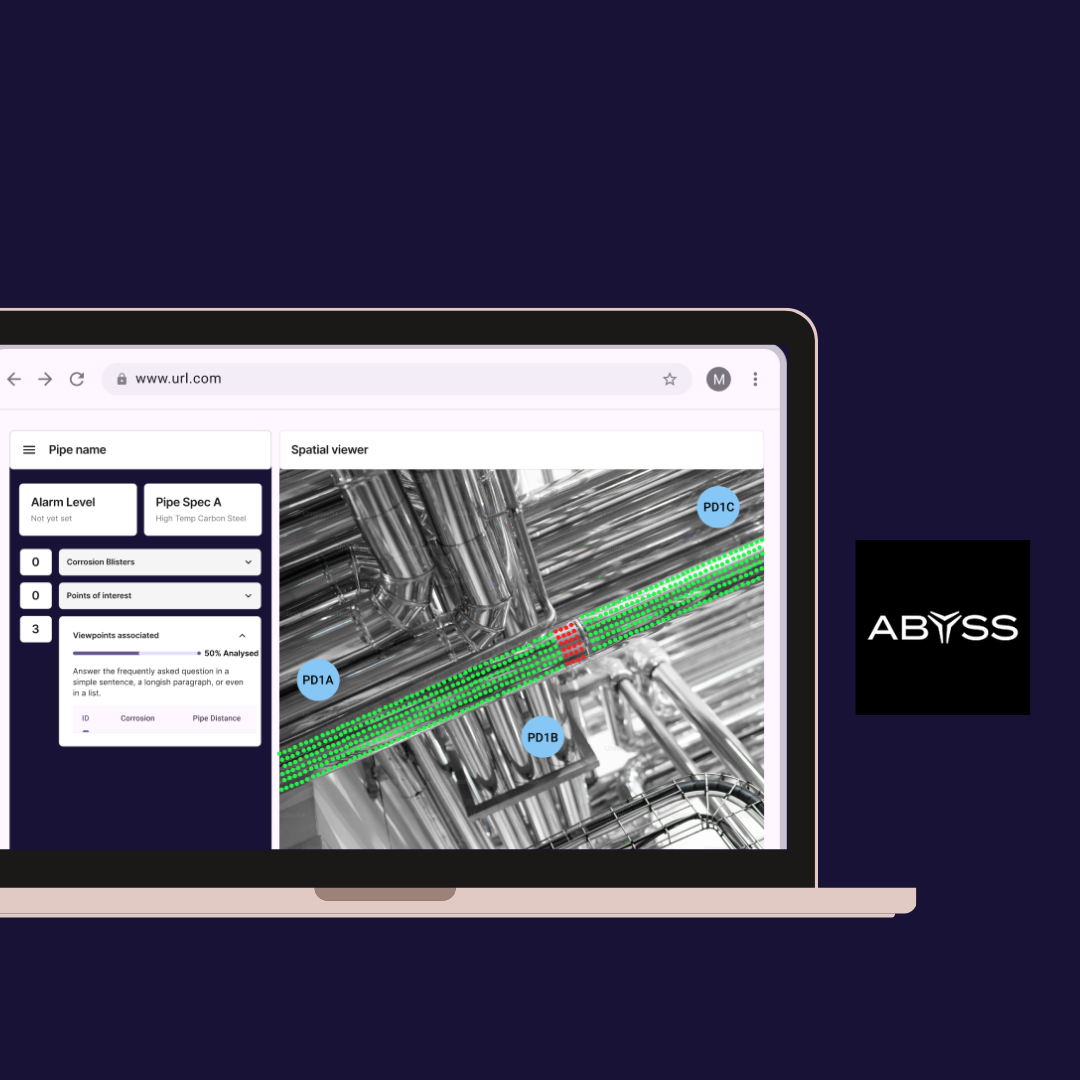

My second task with the company was to understand how clients (MI engineers and field inspectors) utilise Abyss Fabric to identify issues they encounter during their walk-downs. A walk down is where they walk an oil pipe from start to finish in person on an offshore platform assessing it for corrosion, they organise these into inspection campaigns. The success metric from the company for this project was to boost client usage of Fabric.

Field inspector (client user)

Field inspector (client user)

Roles and Responsibilities

I was responsible for the ongoing research and design of Fabric Version 2 from May 2022 to May 2023. I collaborated with a team lead, product manager, product owner, four developers, a machine learning lead, and a customer success engineer

Scope and Constraints

Time and cost weren’t an issue on this project, I had access to five internal users and enough time for research and design alongside ongoing usability testing. I planned the scope at the beginning but this project was in the end deprioritised as a change in management refocused our team back to the findings project as this was seen to already be established value and the right direction forward.

User Problem

Product management had heard from many clients that Fabric was “clunky.” My focus was to investigate the underlying issues causing this perception of the program and assess the value MI engineers currently get from Fabric. Additionally, MI engineers were wasting significant time reading isometric drawings (2D plans of the oil platform) I was tasked with exploring possibilities for integrating this location data into Fabric.

Results

- Validated the current value MI engineers get from Fabric

- Identified a way for MI engineers to receive greater value from Fabric through inspection equipment planning.

- Identified “clunky” related to navigation difficulties the same need internal users had.

- Learned that due to regulations external corrosion findings can only be used as a guide for prioritisation of oil platform focus areas.

Next steps

Oil companies have marine terminals where the ships dock for oil. My third project was to develop a demo of a program that can simplify the risk assessment process of a marine terminal with the value to the client being that they can create their prioritised assessment of the marine terminal and do a cost-benefit analysis in a faster and more comprehensive way.